Timber

All the timber I sell has been milled by me and comes from trees grown on local estates,

farm land and privately owned woodlands.

I air dried my timber for a minimum of one year per inch of thickness with the

exception of Oak boards which are left for an extra year.

The boards are stacked on level surfaces with thin strips of wood (stickers)

between each layer to allow for the free flow of air throughout the stack.

The ends of the boards are sealed to stop moisture being drawn up,

timber takes on water through its end grain and releases it through its

long grain, so by sealing the end grain the drying process is controlled.

Once the drying timber has reached a desired moisture content (MC) the boards are moved under cover into

the wood barn, due to the climate humidity here in the UK air dried timber doesn't normally get below a MC of 15%.

Unlike many timber yards both large and small I keep the stickers between the boards once inside,

this allows for condensation caused by sweating during the summer months to dry at the same time

helps to keep the boards flat, according to my customers this is a key factor for their continued custom.

New stock

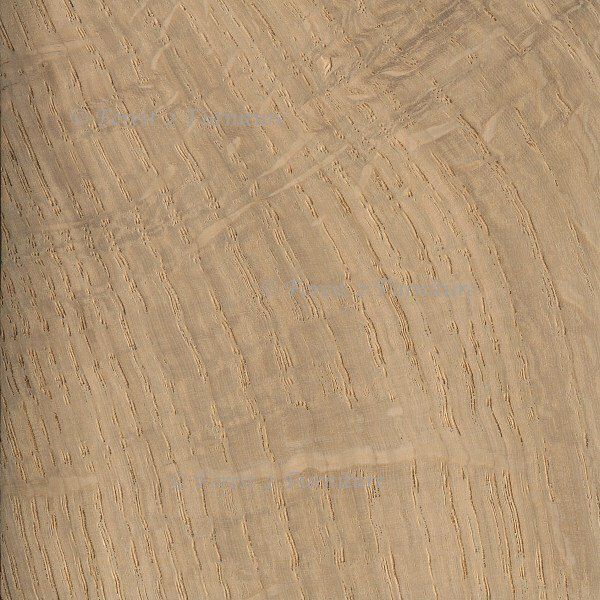

Locally grown English Oak

A large delivery of recently purchased Oak arrived in the yard a few weeks back, grown locally at one of the many

golf courses in the area and felled as part of their ongoing woodland management plan.

Also arriving was an enormous Oak trunk that came from the grounds of a local private school just 3 miles from my premises.

The above Oak trunk is believed to have been approximately 450yrs old when felled and before agreeing to purchase it I

made extensive enquiries to make sure the tree didn't appear on the ancient tree register.

My plan is to mill it quarter saw it into 1" - 1.5" thick boards. As would be expected for a tree of such a great age it has

a substantial amount of rot in the center and therefore not suitable to have slabs cut at full width, which probably

isn't a bad thing as the trunk weighed in at just shy of 7000kg.

Ash and the pole

I've had a short Ash trunk knocking around the yard for the last few months, it has a scaffolding pole sticking out of it. According to the farmer I bought the tree from the pole has a 6" square plate attached to the base and was bolted to the tree some time in the mid 1980's to support a child's swing

With not knowing how far in the base plate was I'd been reluctant to attempt to mill the log but a few days ago I bit the bullet and loaded it onto the mill.

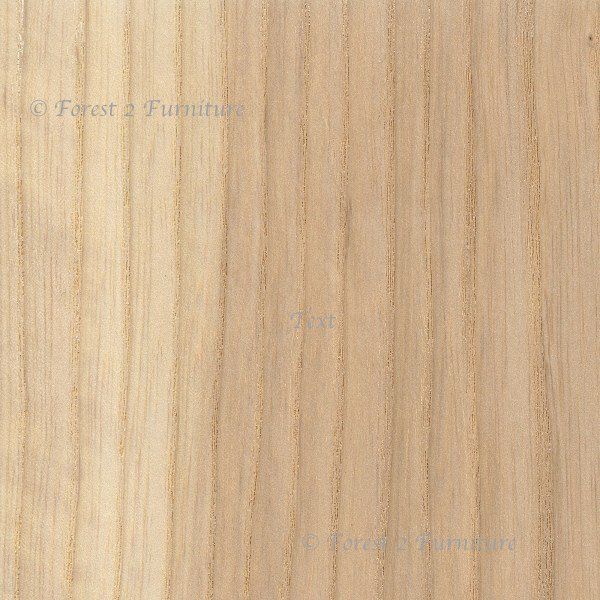

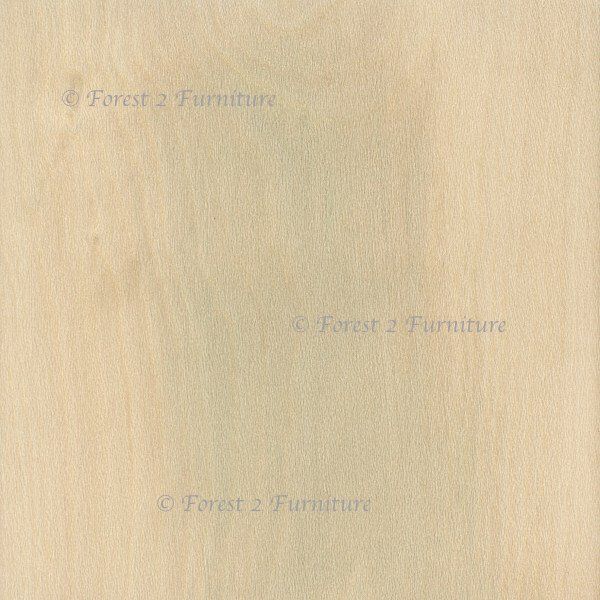

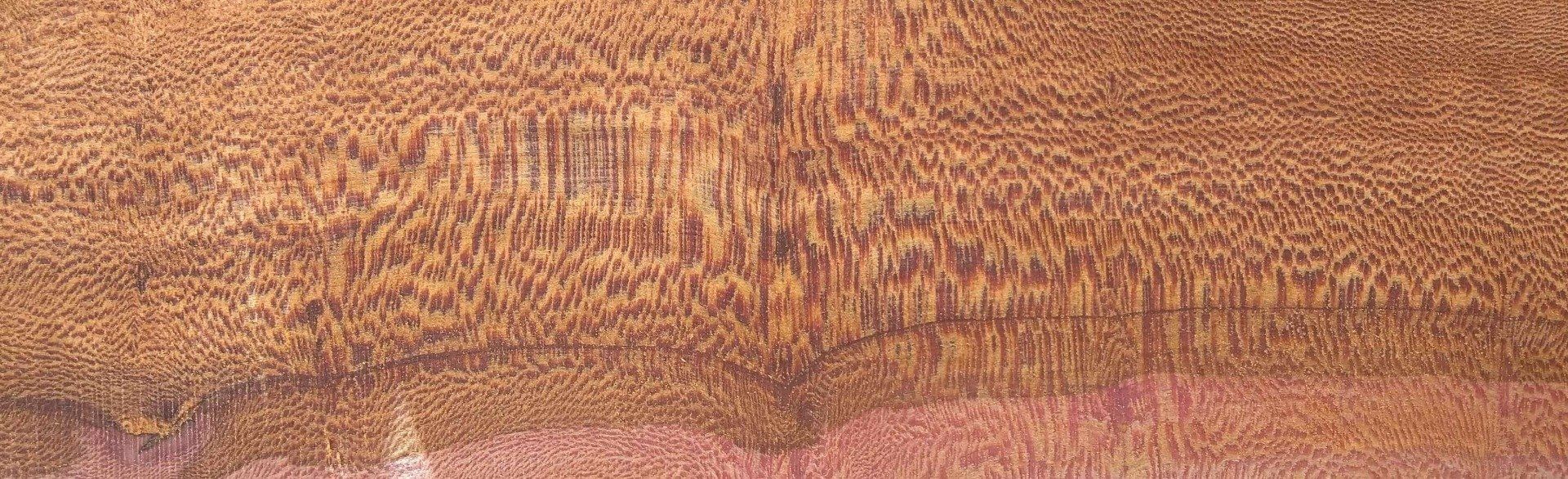

Below are some of the beautiful figured grain planks I finally managed to mill from this difficult little section, well worth it in the end.

Once everything that could be milled from the log was cut, the planks were sticked and stacked then taken to an area where they will remain for the next 12 months to air dry.

Trends may change but timber infestation doesn't;

Over the last decade with the fashion for 'river table' increasing, people have moved away from the traditional craftsman hand made furniture towards the DIY rustic live edge look. Although this look maybe 'on trend' it brings with it certain problems that at first may not be apparent to the inexperienced woodworker.

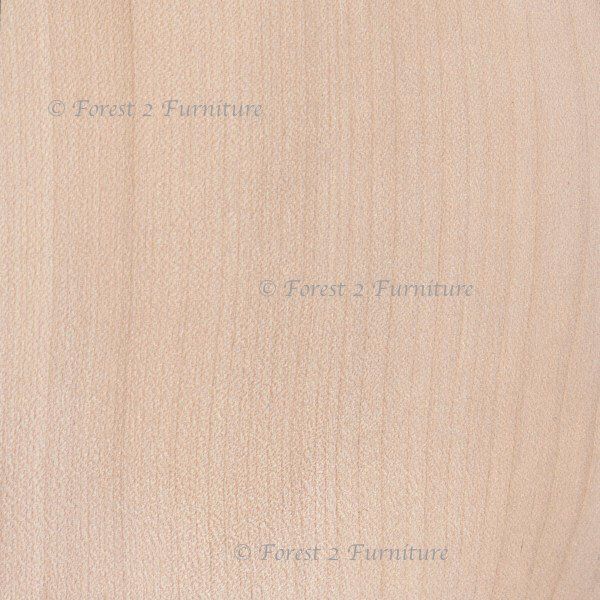

Many of the timbers grown in the UK are susceptible to beetle damage, it's for this reason that I cut and stock very few waney or 'live' edged boards but prefer to stock square edged boards with the bark and soft outer wood removed.

Due to the nature of the business and that there's only me, viewing of the timber is strictly on an appointment bases.

I'm sorry for any inconvenience this may cause you but better to book than find no one in or to busy.